BMW Group Plant Steyr has started series production of the new Gen6 electric engine, which will power the upcoming Neue Klasse models. Milan Nedeljković, BMW AG Board Member for Production, said, “Today, we are laying the foundations for the future of the BMW Group.” Plant Steyr is the first site to produce the sixth-generation BMW eDrive (Gen6) electric engine, which will be shipped to BMW’s global production network for use in the Neue Klasse.

Klaus von Moltke, SVP of Engine Production and plant director at Steyr, highlighted the achievement: “Three years ago, we announced we would build this electric engine in Steyr. Today, we are proud to deliver it. This is more than just a production ramp-up—it’s a commitment to Europe, to technology, and to the future.”

Investment and Expertise

Since the project launch in 2022, BMW Group has invested over one billion euros in expanding e-drive development and production at Steyr. The plant, which has made internal combustion engines for BMW and MINI for over 40 years, will continue to produce diesel and petrol engines alongside electric ones. About 1,000 employees will work in the new electric engine assembly, and by 2030, up to half the workforce could be involved in e-mobility, depending on demand.

Production Details

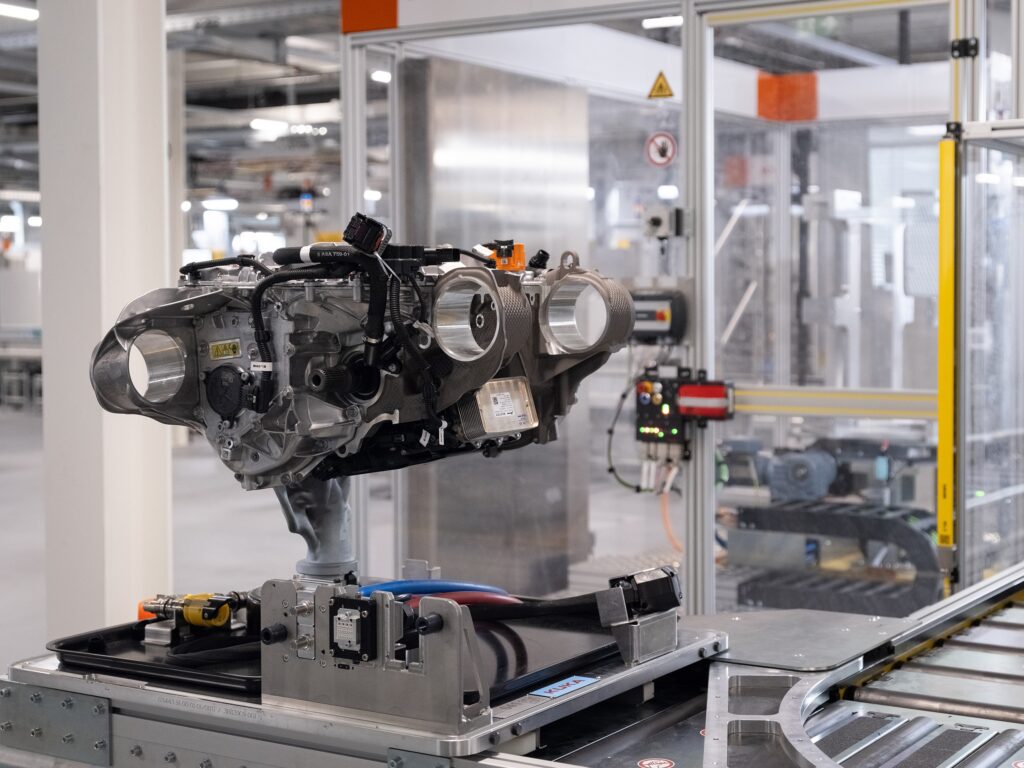

Plant Steyr will manufacture all core components of the Gen6 e-drive, including the rotor, stator, transmission, and inverter. The aluminium housing for the electric engine will be cast at BMW’s Landshut plant and finished in Steyr. The inverter will be produced in a new clean-room environment, marking Steyr’s entry into electrical engineering. The modular production system allows Steyr to build different versions of the electric drive for the entire Neue Klasse range, improving flexibility and cost efficiency.

Gen6 Electric Engine Improvements

The Gen6 electric engine features major upgrades. The rotor, stator, and inverter are all designed for a new 800-volt architecture, which boosts performance and efficiency. The inverter uses silicon carbide (SiC) semiconductor technology to further increase efficiency. Fully integrated into the engine housing, the inverter converts direct current from the battery into alternating current for the motor.

Efficiency Gains

BMW has achieved significant improvements with the Gen6 e-drive. Compared to the previous generation, energy loss is reduced by 40%, costs by 20%, and weight by 10%. These changes contribute to a 20% increase in overall vehicle efficiency. The new powertrain, combined with a high-capacity battery, will give the upcoming BMW iX3 50 xDrive a range of up to 800 km (WLTP).

With these advancements, BMW Plant Steyr is set to play a key role in the company’s electric future, supporting both combustion and electric powertrains as the brand moves forward.